For a wide range of industrial equipment, custom cases offer protection during shipping, storage, and transit. In addition, custom cases are very helpful for protecting delicate devices like computers, electronics, and medical equipment. Custom cases are made to fulfill the specific requirements of the customer. The requirements for the item itself serve as the basis for designing the casing and its accessories. Read More…

One of the top carrying case suppliers, Princeton Case West provides quality carrying cases, custom cases, shipping cases, plastic cases, aluminum cases, tool cases, computer cases, instrument cases, transit cases and ATA cases.

Our cases come in various configurations such as soft sewn cases, hard cases, model cases, exhibit cases, and more. We are experts in contract sewing and there is no project too complex for our experts. With manufacturing experience dating back to 1994 we are confident we can provide you with a top of the line custom carrying case.

At CSE Packaging, we stand as a trusted leader in the realm of carrying cases, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

ZERO Manufacturing prides itself on the production of custom carrying cases made not only to hold valuable equipment but to protect it with state-of-the-art technology. As premium carrying case suppliers, ZERO Manufacturing offers diverse carrying cases including custom cases, plastic cases, ATA cases, transit cases, aluminum cases, instrument cases, computer cases, shipping cases and tool cases.

Ameripack is a leading manufacturer and distributor of carrying cases, Rack Mount and Rotational molded cases. Ameripack can fulfill custom foam inserts, panel mount applications, and since 1989 we have provided our customers with Cases that fit their applications. Over 300 sizes; 6,000 cases in stock!

More Custom Case Manufacturers

Custom Case Design

It's crucial to consider the material for a custom case carefully, and many choices are available to the customer.

These include plastics like:

- high-density polyethylene (HDPE)

- fiberglass reinforced polyester (FRP)

- carbon fiber, rotationally molded polyethylene (RMDPE) or linear low-density polyethylene (LLDPE),

- aluminum, leather

- glass

- nylon

- neoprene

- polyester

- steel

- acrylic

- wood

Industrial designers and engineers also fulfill requests for unique cases created for certain objects like electronics, specialized tools, or medical equipment. Many manufacturers offer stock sizes for products with common dimensions, like television screens, computers, or photography equipment. Even if custom sizes and forms are an option, the most common design is still a box-like container. Custom carrying cases can be ordered by companies or producers who want to protect their products while also needing a special case.

Custom Cases Made by CNC Machines

Some bespoke carrying cases are made utilizing CNC machining, which reduces errors because computers control manufacturing rather than human workers. This technology makes it possible to mill the parts precisely and with tight tolerances. Various materials can be machined using CNC technology. However, different materials have different fabrication and assembly needs. Metal sheets are nailed to a metal frame to create carrying boxes made of metal.

The necessary thickness is achieved by pressing flat slabs of uniformly melted raw metal via a series of roller presses after cooling. The sheets are then welded or bolted together after being bent to the specific shape and dimension. The metal frame is often made of extruded steel or aluminum. For longer life, the corners are frequently strengthened with metal plates.

Molding Plastic Shipping Cases

Numerous molding techniques, such as blow molding, injection molding, and rotational molding, are used to create plastic shipping cases. Fibers used in FRP plastics are first woven, knit, braided, or stitched together before adhering to the matrix's strong plastic surface.

Heavy-duty swivel casters, twist latches, spring-loaded handles, rubber gaskets around the doors for water resistance, recessed latches to meet military standards, molded lugs for secure stacking, shock mounts, strengthened and fortified steel or aluminum framing, buckles, straps, molded tracks for easy stacking, and many other options are among the additional customizable features.

Cutting and Fabricating of Foam

Engineers employ various foam fabrication tools to build the complex layouts that clients require. Another technique is water jet cutting. The precise forms created by large-scale water jet foam cutters' high-pressure stream of water make them perfect for cutting huge or intricate foam objects. Die-cutting uses a variety of die presses to produce a completed product with fine details and is a relatively economical process (particularly for bigger numbers).

Additionally, businesses use 4-axis CNC foam routing machines that remove foam using high-speed rotary cutters. These machines produce exceptional precision because they receive their instructions directly from a CAD program. The CNC process is, therefore, ideal for prototype and one-off production.

Benefits of Custom-Made Cases

- A tailored case makes it simpler to access equipment while safeguarding it during transport. When creating a bespoke case, the case’s contents and how the equipment will be accessed are taken into account.

- The cases can be built from various materials to match the desired level of protection. Therefore, they will completely fit the products and make them as accessible as feasible.

- Custom cases are made with storage in mind as well. Manufacturers create cushioning systems using an internal 3D modeling tool for a fully unique fit and excellent protection. After all, a fully customized cushioning system is essential for a bespoke case to be useful.

Applications of Custom Cases

Medical Industry

The pharmaceutical and medical industries prefer custom cases that satisfy strict functional requirements and have a pleasing look. More importantly, this industry demands that its machinery always be secure. Medical cases provide the best packaging option for the secure transport of priceless medications, tissues, and blood. Also, custom cases ensure that medical equipment is meticulously organized and add extra security for the most delicate things.

Lighting Industry

The majority of lighting fixtures are sensitive and should be handled with care. Industrial shipping crates can be used to ship various lighting accessories, including small LED lights, overhead streetlights, and lighting gear for concert halls, theaters, and more, since they are fragile.

Athletics

Custom cases protect sporting accessories, gear, and uniforms from potential impacts, jostling, and other environmental factors.

Choosing the Correct Custom Cases Manufacturer

To make sure you have the most productive outcome when purchasing Custom Cases from a Custom Cases Manufacturer, it is important to compare at least 4 or 5 Companies using our Custom Cases directory. Each Custom Cases Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Custom Cases company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Custom Cases businesses with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

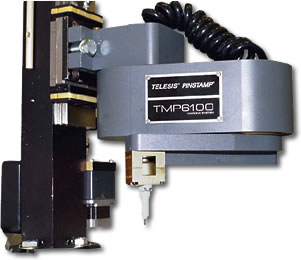

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services